On-site consultation

In order to guarantee an optimised further use of existing components we invest time in a thorough examination of your machinery and draw up a cost estimate on the basis of this.

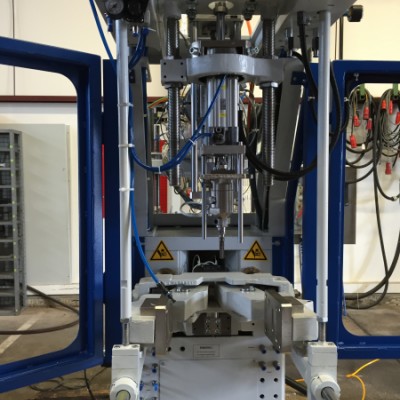

Disassembly, cleaning and treatment of individual parts

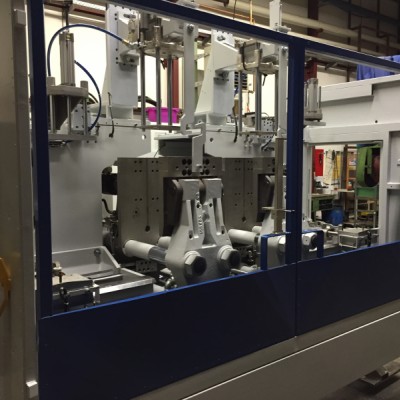

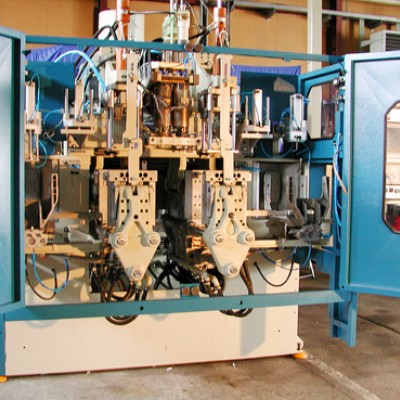

In our factory the machine is completely disassembled down to its individual parts and cleaned. Casing and frames are painted with two-component paint.

Installation of new components

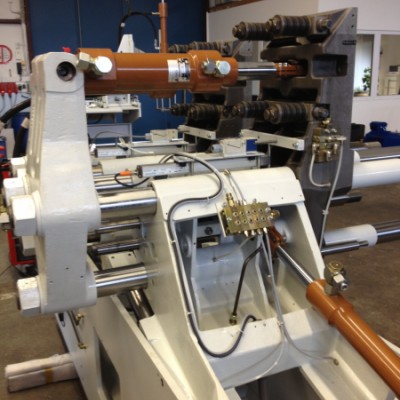

Mechanics: All sockets, bearings and capping pieces are routinely renewed.

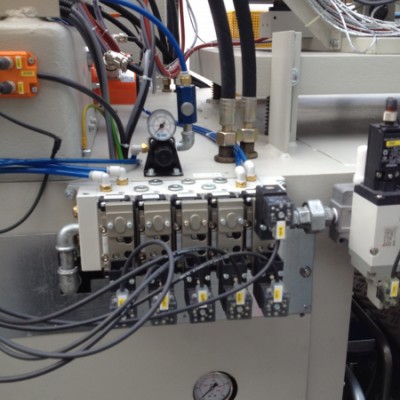

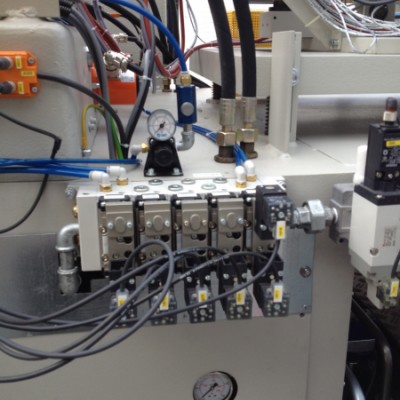

Hydraulik: All valves, cylinders and pumps are checked. All seals and tubes

are renewed. Defects Components are replaced.

Pneumatik: All the components are routinely replaced by ISO - parts. (valves, regulators,

cylinders, etc.)

Electrics: The control cabinet is completely rebuilt. All electrical components as well as the wiring are renewed. An SPS control with graphic display is installed. This is adapted and optimised to the particular machine. Electric motors are overhauled, rewound or replaced.

Safety: The machines are equipped with the latest safety components:

- Accumulator

- Safety blocks

- Safety valve

- Safety switchgear (e.g. PILZ)

- Limit switch

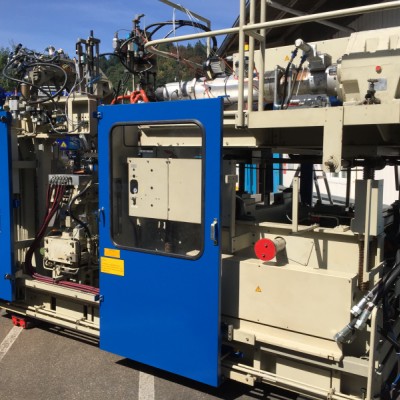

The machine is subsequently assembled, checked and prepared for transportation. If required, we also install the machine in your plant.

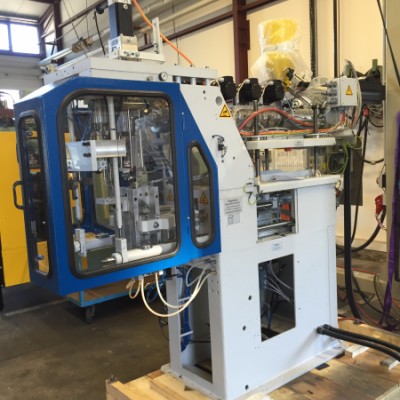

Closing work / result

our RETROFIT - machine is approx. 60 % more economical than a new machine, now has the latest standard of safety, is considerably more powerful due to the optimisation of the blowing technology (increase in performance of approx. 20% to 30% per unit),

saves energy due to the installation of a new motor.